World premiere of Sumitomo (SHI) Demag’s most economical, clean, low energy consumption and high-performance all-electric packaging machine to-date.

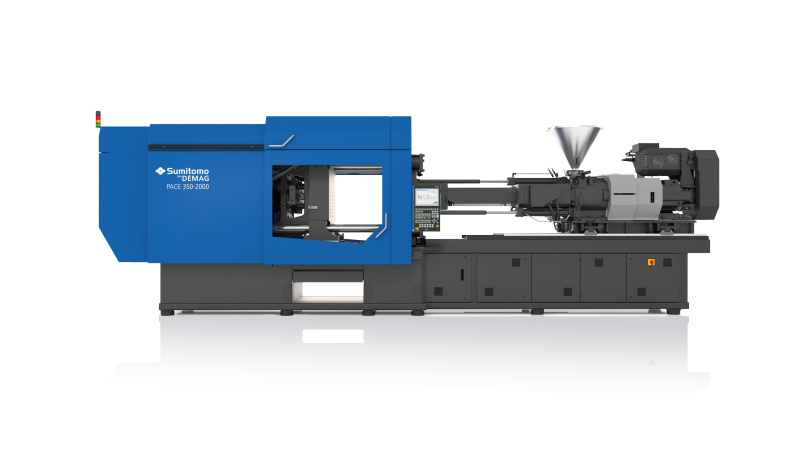

Sumitomo (SHI) Demag Plastics Machinery GmbH, Schwaig – October 2022. K 2022 is the stage for the first global presentation of the very latest all-electric innovation from Sumitomo (SHI) Demag – PAC-E. Engineered specifically for manufacturers of beverage closures and thin walled packaging applications, the new all-electric, high-speed injection moulding machine builds upon the success of the El-Exis SP – renowned worldwide for being the best and fastest packaging machine on the market. The addition of PAC-E sets another new industry benchmark for energy consumption and cleanliness, exclaims Arnaud Nomblot, Director Business Development Packaging.

At the international trade fair in Düsseldorf, the company will initially demonstrate the new machine’s capabilities and sustainability credentials on a 350 ton clamp force PAC-E model. Three additional clamp force variants – 420, 250 and 300 tons – will subsequently follow in this order confirms Nomblot.

” PAC-E is a global development project that combines all our company know-how from Germany and Japan,” Nomblot reveals. The toggle levers, plates, tie bars and plasticising elements, including the screws and cylinders, were developed in Germany, while the electric drives and the newly developed injection unit with excellent injection performance were derived by the Group’s Japanese parent company.

Two critical innovations differentiate PAC-E from the existing hybrid packaging series. Notably, the solely electric-driven axes deliver up to 50 percent in energy savings. Converting a 30 cents (€) per kW/h saving in electricity consumption, this can save manufacturers approximately €70,000/ USD 71,285 per annum when measured against a high-speed hybrid packaging machine. Additionally, the lubrication of the toggle lever no longer causes cleanliness issues; being a completely closed circuit design it is leak free. Oil is instead extracted, filtered and recycled. This eliminates the need to clean the toggle lever, which has the added benefit of reducing oil consumption for customers.

Smaller footprint in every sense

Not only is the reduced energy consumption of PAC-E less resource intensive, the machine’s dimensions are more compact. Meeting calls from customers for space-saving machines. The Director of Business Development Packaging affirms that although the PAC-E packaging machine is shorter and narrower, it maintains the excellent performance of the existing hybrid series combined with significant energy efficiency and greater cleanliness. Protecting packaging manufacturers against further resource shortages and uncertainties, as well as volatile energy prices.

With its injection capacity of 550 mm/s, PAC-E can also be used for thin-wall and food packaging with IML, confirms Nomblot. “This machine will enable processors to produce even thinner and lighter packaging items, resulting in a significant reduction in raw materials, waste and shipping costs.” Another excellent example of how Sumitomo (SHI) Demag continues to deliver against its Act! Sustainably ethos.

The Group remains completely committed to sustainability, states the packaging expert. “As part of this ecological commitment we are taking decisive action by stating all future innovations, machines and equipment are now totally manufactured with this mission and the EU Digital Product Passport (DPP) in mind.”

To demonstrate the capabilities of PAC-E, the company’s K 2022 showcase (Hall 15, Booth D22) will use a 72-cavity mould supplied by Z-Moulds to manufacture 2,100 26/22 still water beverage caps every minute. The HDPE copolymer Eltex HD5211EA-B is supplied by Ineos Olefins & Polymers Europe, with Polar Bear introducing its advanced cavity cooling and tool dehumidification system. For optimal quality control, 100 percent of all the beverage caps pass through the Intravis camera inspection system.

Market launch of PAC-E commences in mid-2023 starting with the 350 ton. The company plans to roll out the remaining clamp force sizes in succession.